The first facet of our vision aimed at reshaping the manufacturing industry,

confronting its persistent challenges. 'Autonomous Product/Component

Fabrication' wasn't merely a solution; it was our declaration of intent to

transform the landscape. By addressing manufacturing inefficiencies and

operational bottlenecks, we envisioned a future where every product is a

testament to precision, efficiency, and seamless automation. This side of

our vision sought to transcend the ordinary, pioneering a manufacturing era

defined by autonomous processes and unparalleled innovation.

The other side of the coin unveiled UiPath's extraordinary capabilities, far

beyond the routine tasks of scraping, Excel manipulation, and mail

monitoring.

We imagined a UiPath bot as not just a digital assistant but a dynamic

force.

-

Have you ever thought a bot autonomously steering a drone to accomplish

specific objectives.

-

Envision UiPath stepping into the realm of creativity, becoming an

artist capable of drawing, crafting poems, and even scripting.

-

Picture a bot transforming into an on-call agent, proficient in

resolving hardware issues—whether with your TV, IoT device, or any other

appliance.

|

Mr.Bot as the Pilot and Artist

|

In our unique exploration, we ventured into uncharted territory,

presenting a prototype where a UiPath bot autonomously undertook research,

designed components, and oversaw the entire product fabrication process.

This side of our vision was a testament to UiPath's potential to redefine

the boundaries of what a bot can achieve.

The Problem

To understand the problem, we first need a clear idea of what the As-Is

process of product component manufacturing entails.

The process primarily resides within the civil/mechanical domain, yet

its fundamental structure is broadly applicable across various

domains, with minor variations. It comprises three key entities: the

end customer, the service provider, and the manufacturer. Notably, our

focus lies predominantly on the service provider and manufacturer

sides of this intricate process. The end customer, desiring

installation or procurement, initiates the process by submitting an

order request to the service provider. Subsequently, the service

provider processes the order, executing a CAD design to determine

final costs, followed by the generation of an invoice. The approved

order is then forwarded to the manufacturer. Once the end customer

settles the payment, the manufacturing phase commences, culminating in

the delivery of units to the customer's location, where installation

takes place.

However, at each juncture within this end-to-end process, substantial

human effort is invested, grappling with operational inefficiencies,

enduring prolonged production cycles, and accommodating an escalating

demand for precision and scalability. Although human-intensive

workflows embody considerable expertise, their progress is impeded by

limitations in speed and repeatability.

Case Study On Perforated Plates

Let's delve into a real case study to gain insights into the domain, a

crucial step in understanding the upcoming technical aspects.

-- What is a perforated plate?

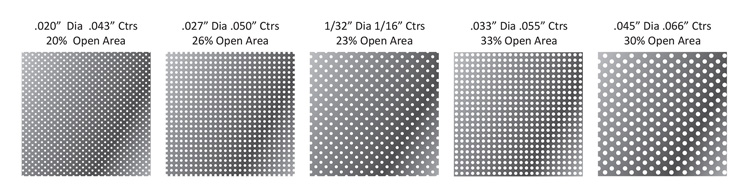

Perforated plates, versatile sheets crafted from metals or other

materials, feature an array of strategically placed holes, each designed

with specific specifications. These plates serve multifaceted purposes

across various industries, acting as integral components in

construction, engineering, and design. Beyond their structural

functionality, perforated plates are widely recognized for their

aesthetic appeal, offering a unique blend of form and function. The

deliberate arrangement of perforations not only allows for enhanced

airflow but also provides an artistic touch to architectural elements.

In applications ranging from acoustic panels to filtration systems,

perforated plates showcase adaptability, offering tailored solutions for

diverse needs.

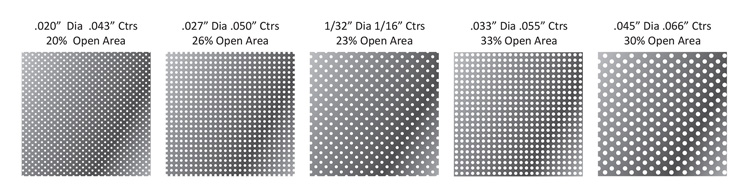

There are a lot of manufacturers across the globe producing perforated

sheets at various volumes. Attached below is a sample catalogue. A

specific manufacturer is selling sheets with the specifications mentioned,

which will be further procured for installation.

|

A sample perforated metal plate catalogue from a

manufacturer

|

Now, a customer will place an order with a service provider to install

perforated sheets, whether for a building's partition wall or roof. The

service provider will gather details such as sheet brand and model

number, then create a design based on the product specifications

outlined in the manufacturer's catalogue. This design process determines

the required number of sheets and the total cost. Subsequently, an

invoice is generated, and the design is sent for fabrication, with the

manufacturer handling delivery. Finally, the construction team installs

the sheets according to the approved design, as shown in the image

below.

It's important to note that this is a high-level, simplified case

study, intended as a starting point for implementing automation and

driving innovation within this process. Similar to perforated

sheets, there are countless products in the market that undergo the

same process like wire mesh, cylinders, grating sheets, etc.

|

A building partition wall built using perforated plates

|

Understanding this domain knowledge provides a foundation, and now,

let's delve into the technical aspects to explore how automation can

enhance and innovate this process.

UiPath + (Gen)AI = Autonomous

UiPath synergizing with GenAI heralds the era of autonomy, where

intelligent automation seamlessly intertwines with the power of next-gen

artificial intelligence. Together, they forge a transformative alliance,

propelling industries towards unprecedented efficiency, innovation, and a

future where processes operate autonomously, guided by the brilliance of

advanced AI technologies.

Drawing inspiration from the

successful fusion of intelligent automation and advanced AI, our approach

envisions the creation of an autonomous system that seamlessly integrates

with the existing manufacturing landscape. By deploying cutting-edge

technologies, we aim to streamline processes, eliminate bottlenecks, and

empower the service providers and manufacturers with a transformative

toolkit. This synergy, marked by UiPath's unparalleled automation

capabilities and GenAI's cognitive prowess, charts a course towards a

future where component fabrication transcends human limitations, operating

autonomously with precision, speed, and adaptability. Our mission is to

not just innovate but to redefine the manufacturing paradigm, unlocking

new possibilities in the realm of autonomous product/component

fabrication.

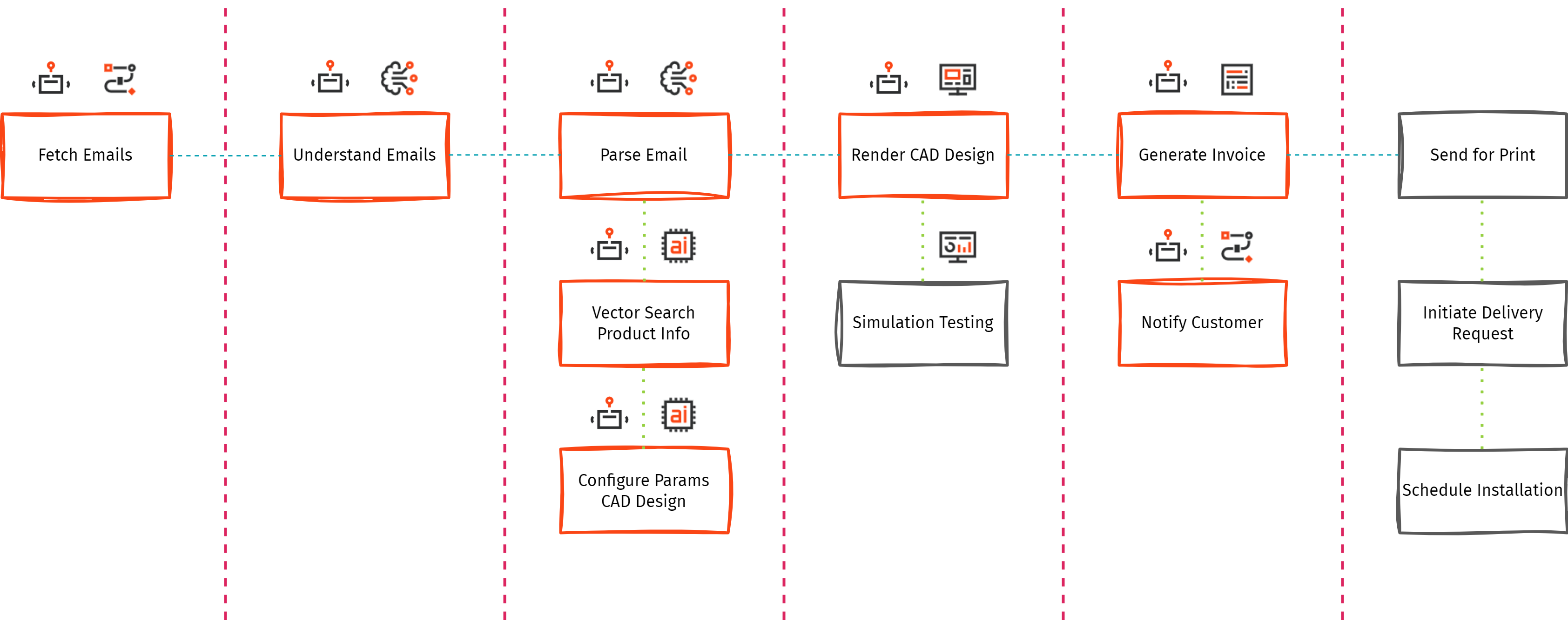

|

UiPath Solution Architecture

|

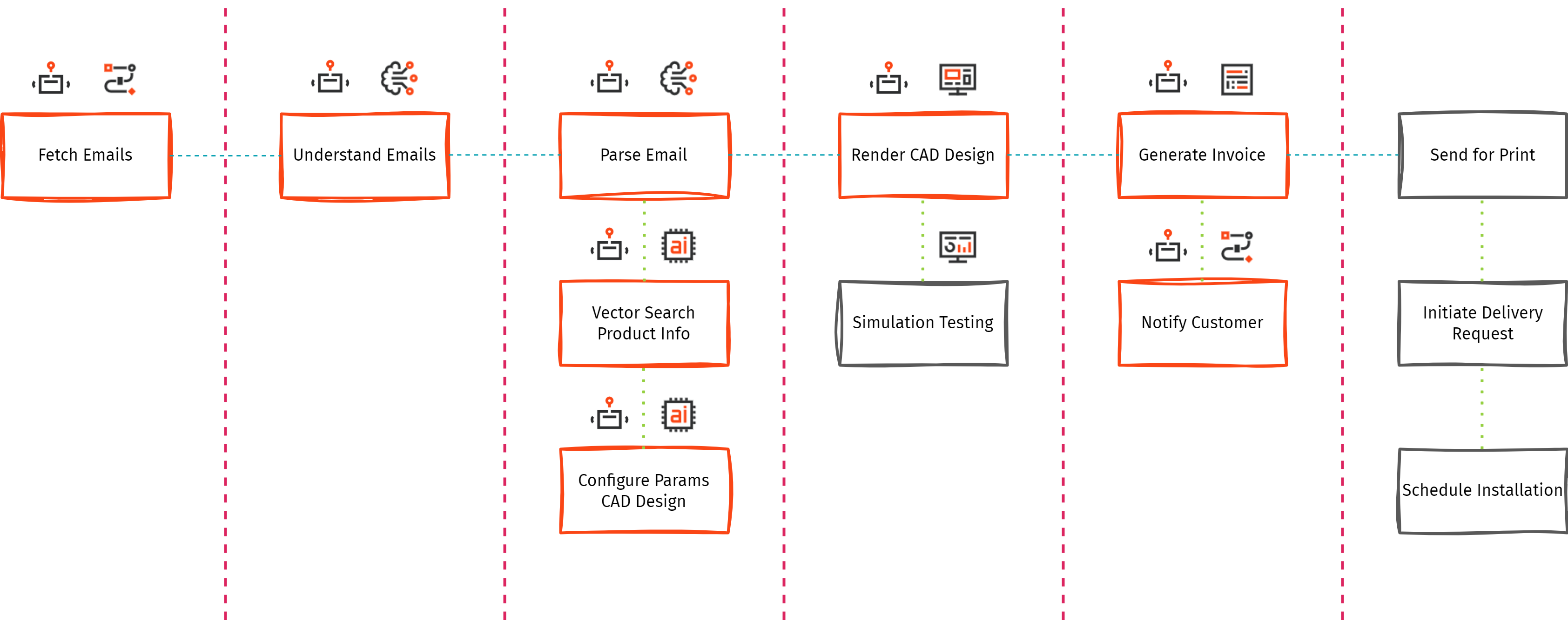

The overall plan includes six main parts to smoothly handle different

aspects of the process: Communication Channel, Product, CAD Design,

Invoice, and Printer. Think of it like building blocks that work

together. UiPath Studio is where we create the step-by-step instructions

(workflows), and the Robot is like the doer that follows those

instructions precisely. Orchestrator is like the director making sure

everything is in sync. The Integration Service connects UiPath to emails

and AI tools for easy communication. UiPath AI Center adds a touch of

smart learning to the mix. We also include user-friendly GPT models like

GenAI and Bard, plus a creative tool called OpenSCAD for design. All

these elements come together to make autonomous component fabrication a

reality.

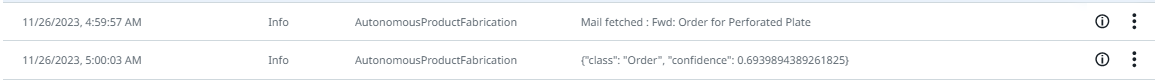

Communication Channel: We are considering email as the

communication channel for this use case, but, essentially, it can

originate from any source, such as a chatbot, request form, or e-commerce

platforms. We will utilize UiPath's integration service to seamlessly

connect to the mailbox, triggering automation based on mail events for

every email received. This approach allows us to instantly fetch all

emails, and their metadata will be added to the Queue for processing.

|

Order Email Request from a Customer

|

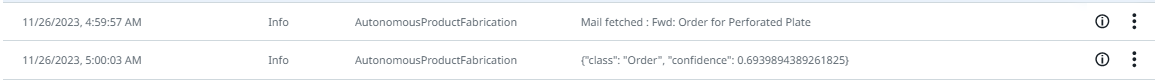

Email Classification: Once the email request is submitted for

processing, we need to categorize the email. This categorization helps the

automation bot determine whether the received email is an order request or

something else. To achieve this, we employ UiPath's Specialized AI with AI

center, utilizing either the text classification model or the NER model.

This process assists in accurately tagging the email under specific

labels.

|

Email Classification Result with UiPath Spl. AI

|

GPT's Magic: We leverage OpenAI's GPT to parse product information

from received emails. GPT seamlessly integrates with UiPath through the

Integration service, authenticated using an API key. The bot can then

communicate with GPT for any queries. In this process, it sends the email

content to GPT, extracting product data such as the ordered item, brand,

area dimensions for installation, and potentially its type along with the

delivery date.

|

UiPath Integration Service with Open AI

|

Following the extraction of product details from the email, the next

crucial step is to search for the product in the global catalog or

datasheet to obtain specifications using web crawling combined with

vector search. This step is paramount for designing the product into

specified area dimensions, whether it be a building roof or a wall. To

facilitate this search, we rely on Google's BARD AI, connected with

UiPath through an API service. This connection enables us to submit

queries with the product model number and brand, obtaining the necessary

product specs required for the design, including sheet length, width,

and hole diameter.

|

Product specifications in Manufacturer website which will be

fetched by BARD AI

|

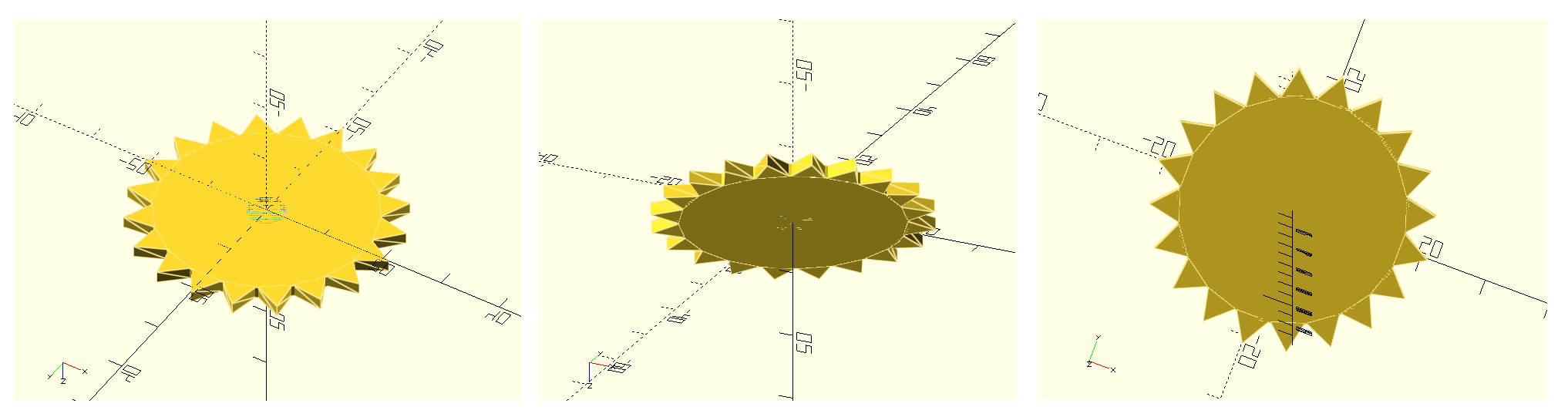

CAD: Computer-Aided Designing, is a software

program that enables users to create and modify 2D and 3D designs. With

CAD, users can generate drawings, prototypes, and manufacturing

instructions. This forms the core, out-of-the-box approach in our use

case, where a bot is created to design a product based on various

parameters and smart AI intelligence. Now equipped with area details and

product specifications, including the perforated sheet, it's time to

generate a CAD script for rendering. We utilize the OpenSCAD open-source

CAD tool, where scripts and configurations are employed to generate

designs. OpenAI's GPT once again comes into play, generating the

OpenSCAD script based on parameters from previous steps.

|

OpenSCAD Script Metadata file by UiPath Bot with GPT

|

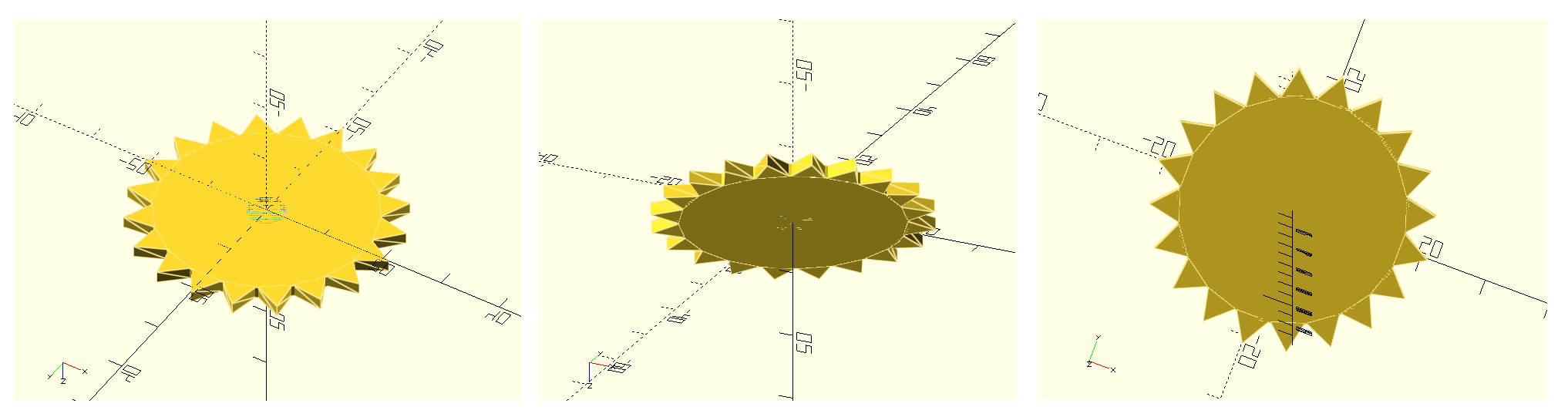

This script is then fed into the OpenSCAD Windows service to render the

product drawing according to the customer's requirements.

|

CAD drawing output by Bot: Single perforated sheet to the

left, Perforated sheet filled for the area dimensions to the right

|

**Simulation Testing: In CAD, simulation testing is vital for

validating product designs, assessing factors like structural

integrity and performance before physical implementation. Automation

transforms this process, enabling systematic and rapid execution of

tests. Popular simulation methods, including Finite Element Analysis

(FEA), Computational Fluid Dynamics (CFD), and kinematic simulations,

evaluate structural strength, fluid flow, and motion, respectively.

Leveraging automation frameworks, the CAD bot conducts these tests

seamlessly, ensuring that the designed product meets rigorous

standards. This accelerates the testing phase, enhances accuracy, and

contributes to the overall efficiency and reliability of the product

development lifecycle.

Invoice Generation: To create invoices, we utilize third-party

tools through an API request, where the bot transmits necessary

metadata. The third-party service responds by providing a PDF invoice

file, subsequently sent to the customer for billing.

|

One of the Invoice generated by UiPath Bot

|

**Send for Printing & Schedule Delivery: Manufacturing has

also embraced advancements like cloud or local printing, including 3D

printing and more. Now, the bot takes charge of the printer hardware,

whether via a local connection or cloud-controlled connectivity, to

transmit the product design file or metadata to the 3D printer and

initiate a print request. Simultaneously, it schedules delivery and

installation with the manufacturer, accomplished through a form in the

official portal or perhaps via a CRM.

**Plan for the future, not implemented at the moment.

This proof of concept serves as a testament to UiPath's versatility

and capability to revolutionize the end-to-end manufacturing flow for

product fabrication. The prototype showcases UiPath's prowess not only

in streamlining stringent operations like order processing but also in

addressing critical aspects of the manufacturing process, such as CAD

design and simulation testing. By seamlessly integrating automation

into these intricate processes, UiPath demonstrates its transformative

potential in enhancing efficiency, precision, and innovation within

the manufacturing industry. This marks a significant step towards a

future where UiPath plays a pivotal role in shaping the landscape of

automated and intelligent manufacturing.

Ready to be part of the revolution in how we create things?

Well, here's your chance! Our project is now Open Source,

available for everyone to contribute and get started. Join us in shaping

the future of manufacturing automation with UiPath. Your contributions

can make a real difference, making manufacturing smarter, more

efficient, and open to all. Why not jump in and be part of this exciting

journey?

Joining our project offers numerous benefits, not only for the

collective improvement of manufacturing processes but also for

individual growth. Contributing to our open-source project offers a

unique opportunity for skill enhancement through hands-on experiences

and real-world challenges. Engage in collaborative learning within a

global community, exchanging ideas and gaining insights across diverse

domains. Build a robust resume by showcasing your commitment to

innovation and community-driven development, while also enjoying

networking opportunities and making impactful contributions that leave

a lasting mark on the manufacturing landscape.

Universal Automation

Our project can extend beyond manufacturing, positioned as universally

applicable, it transcends industry boundaries, catering to domains

such as Automobile, Aeronautical & Defense, Electrical &

Electronics, and Civil & Architecture.

We explored a sample scenario in the automobile industry, attempting

to generate a gear based on a customer order request. Please note,

this is a very high-level example. Fortunately, the UiPath bot was

able to draft a gear structure by leveraging the entire solution flow

designed above. While the result may not be entirely accurate, it

demonstrates the bot's capability to generate a basic gear structure

|

CAD design of a helical gear with 20 teeth by UiPath Bot

|

Our future enhancements include,

-

Utilizing advanced requirement and behavior analysis, our upcoming

feature will intelligently recommend vendors, streamlining the

selection process for optimal choices tailored to your project

needs.

-

Before the physical fabrication process begins, our system will

conduct thorough stress and thermal performance tests, ensuring

robustness and reliability in your products. Stay tuned for a future

where perfection is tested before it's built.

-

We will also aim to minimize output distortions, ensuring

unparalleled precision and expanding the scope of possibilities.

Experience a new level of refinement as we fine-tune our models to

deliver optimal results for your automation needs.

-

Embracing the smallest units of automation, our project will be

transitioning to an 'Automation Atoms Framework' in near future.

This innovative approach breaks down complex processes into

elemental components, promoting flexibility, scalability, and

efficient orchestration. Each 'Automation Atom' functions as a

self-contained independent process, collectively forming a powerful

and adaptable automation ecosystem.

-

Acknowledging the diverse demands of the manufacturing landscape, we

will be elevating our design module to adeptly handle intricate

nuances like skew and design irregularities. This transformation

ensures it is exceptionally adaptive to the diverse challenges

presented by variations in design.

As we traverse the landscape of manufacturing innovation, our journey

with UiPath's AI Hackathon and the development of 'Autonomous

Product/Component Fabrication' unveils a transformative

chapter. We've explored the synergy between UiPath's cutting-edge

AI capabilities and the vast potential of automated

manufacturing. The Community Avengers, the Brainy Fools team, and

the collaborative spirit of the hackathon underscored the power of

organized innovation.

In closing, our journey doesn't end

here; it evolves. The path ahead holds exciting possibilities, and with

Universal Automation as our guiding principle, we stride confidently

towards a future where automation knows no bounds. Join us on this

remarkable expedition of innovation and transformation.

Want to experience the future of healthcare firsthand? Explore our

health care based open-source project, "Doctor's Assistant" and contribute to democratizing healthcare access through AI

innovation with UiPath.

Make sure to follow UiPath's official channels to stay updated on

the latest news, releases, and events. Subscribe to our blog,

follow our social media accounts, and join our community forum to

be part of the conversation and connect with like-minded

individuals. Stay ahead of the game and keep learning with

UiPath!

No comments:

Post a Comment

Let me hear you 🙌✨